One of our readers responded to an article commenting, “I know much more, but if I could just win some of these contracts we would be golden”. The fastener industry is competitive. Recently, we added a tally of number of competitors to our contract award display at BidLink, which is yielding some interesting results. An analysis of defense contracts awarded to the fastener industry over the last few years reveals a high number of competitors, even for some relatively small contracts.

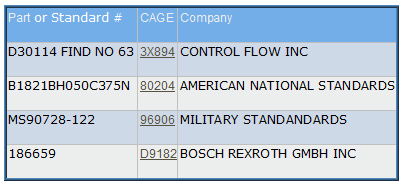

The highest number of competitors for a fastener contract in 2011 was for contract no. SPM5A211M2084, where forty one (41) companies submitted bids. The contract was only valued at $10,270 and was awarded to Quality Socket Screw Corporation (cage code: 5N116) for 2,600 steel studs. The winning price was $3.95ea. Quality Socket Screw Corporation in Englewood, FL has 22 registered NSNs with the Defense Department and have received over 9,000 contracts and delivery orders.

There were twenty two (22) competitors for SPM5AY10D0113, a long-term contract awarded to Columbia Nut and Bolt (cage code: 51792) on 9/30/2010. The contract covers 29 stock numbers for studs, close tolerance screws, self-locking nuts and quick release pins. Several delivery orders against this contract are for large quantities of self-locking nuts, NSN 5310-01-011-3085. The Defense Department has ordered over 185,000 of these against this contract for $1.13ea. That’s over $200,000 in sales on this one part. Columbia Nut and Bolt has $20 million in annual sales with 700 employees.

The key to winning these contracts is knowing the competition by using online resources to research before you bid. Start by exploring existing contracts to see who is winning and at what price. The Government is moving away from small orders and toward the use of long-term contracts to streamline the process of procurement. In stead of issuing an RFQ for each order, they are consolidating many requirements into a single contract, then issuing delivery orders against that contract. The window of opportunity for competitors is when these contracts expire. The contract above expires on 9/29/2012.

Knowing when these contracts expire, the winning price, and how many competitors are participating can put you in a good position to compete for the next award. Also, the Defense Department is required to award a certain percentage of contracts to small businesses. The target for 2011 was 23%, or $12 Billion in small business awards. Each contract is designated as small business or large business.

If a contract is for small business, companies below a certain size (usually < 500 employees) will get certain advantages. If a small business and large business are competing and offer the same price, the small business will likely win the contract. Solicitations can be re-classified as small business by contacting the the buyer who issued the contract, and proving that you can supply the parts. To learn more about small business set-asides, check out sba.gov. Of course, you can always search BidLink for contracts that are small-business set-aside.

BidLink.net is a provider of defense industry information for contractors worldwide. This data includes millions of defense contracts, procurement history, part numbers and vendor details. This unique combination of resources allows BidLink to monitor and extract important information for the defense contracting industry. BidLink.net, based in Washington, D.C., provides bid consolidation, searching and notification services, as well as part number (NSN) lookup to many military activities and thousands of private companies around the world.

Comments? Send them to news@bidlink.net.

This article was written exclusively for “Fastener Journal” magazine .

Tweet