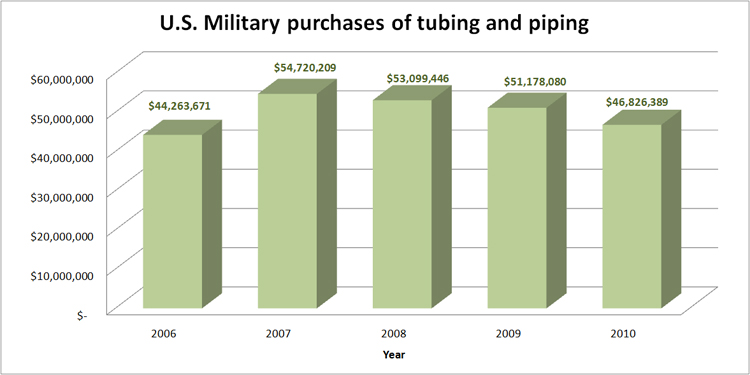

Despite a weak economy, U.S. Defense Department demand for tubing has been stable over the past five years with annual purchases totaling nearly $50 million. Metallic tube and pipe is an integral part of the military and all its divisions. Aircraft, navy ships and vehicles would not exist without the use tube and pipe. Construction of barracks, repair and maintenance of large and small equipment are also included. All types and sizes from simple dimensional stock to custom assemblies are consumed by the military. Numerous types of distributive systems on-board navy ships use piping everywhere to deliver drinking water, provide fire suppression, compressed air, steam, and hydraulic fluid. The typical aircraft carrier spans over 1000 feet in length and uses a lot of pipe.

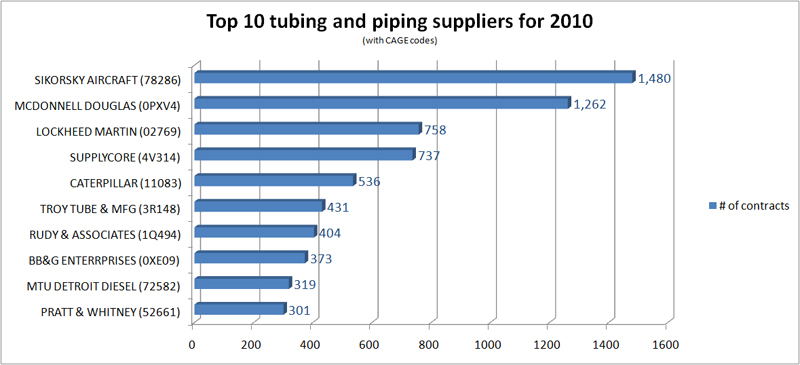

An analysis of the competitive landscape exposes Sikorsky Aircraft as the top contractor by number of contracts with just shy of 1,480. Several of the major players are aerospace suppliers, showing the importance of tubing and piping to the aerospace industry. Sikorsky Aircraft is based out of Stratford, Ct with 17,457 employees and annual revenues of over $5 Billion.

Prime Manufacturer Sikorsky won the largest award in 2010, long-term contract # SPM4AX09D9404. It covered many parts including a 1/2 inch metal tube assembly (NSN: 4710-01-095-6934) made from aluminum alloy 5052. The contract was originally awarded to the company on July 8th 2005 under contract number SPM400-05-D-9413. It has a base period of one year with options to extend (both bilateral and unilateral) for up to 10 years. The total contract amount for the base period of one year was an estimated value of $74,805,917.23, and covered dozens of different parts. It contains several National Stock Numbered items sole source to Sikorsky. The contract is currently in its 5th year. It also includes a performance fee which gives the contractor the ability to earn an extra 14% to 25% by exceeding the contract requirements for on time delivery during their evaluation period.

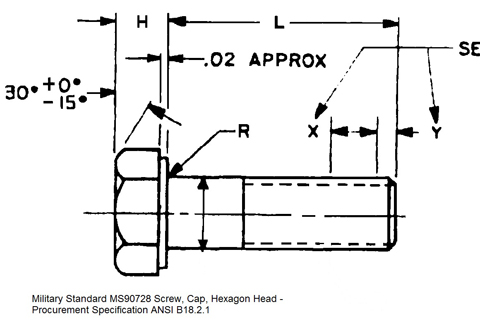

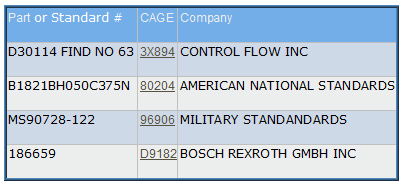

Prime manufacturers typically have subcontractors produce many of the components used in their end items, such as the Black Hawk helicopter manufactured by Sikorsky. The U.S. Government is always searching for additional suppliers of items that they consume, especially items which have only one source or sometimes no source. Companies interested in increasing their government sales will typically seek out these “sole source items” as the competition is limited, therefore potential profit margins could be high. The process many companies use in becoming an additional source is as follows: Determine which items are worth pursuing, obtain the actual part from the government or data if available, reverse engineer the item and become an approved source; possibly the only source.

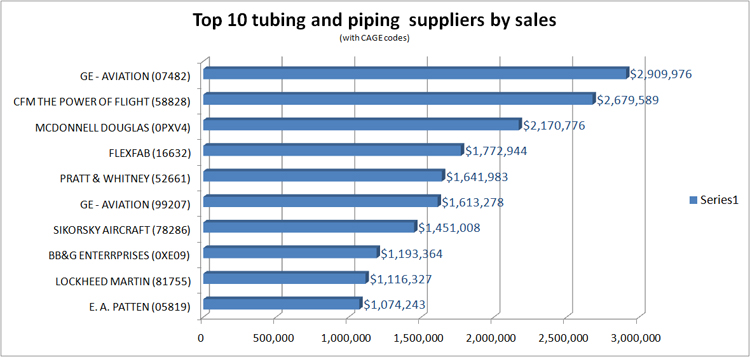

An analysis of annual sales reveals a different picture with GE Aviation taking the number one spot. Much of this is awarded through long-term contracts, where a vendor will win a bid to supply a list of parts to the Defense Department over several years. The Government will issue periodic delivery orders against these long-term contracts, reducing the need for a competitive bid every time they stock up. Periodically, these contracts will expire, allowing prudent contractors to take the business for themselves.

BidLink.net is a provider of defense industry information for contractors worldwide. This data includes millions of defense contracts, procurement history, part numbers and vendor details. This unique combination of resources allows BidLink to monitor and extract important information for the defense contracting industry. BidLink.net, based in Washington, D.C., provides bid consolidation, searching and notification services, as well as part number (NSN) lookup to many military activities and thousands of private companies around the world.

This article was written exclusively for TPJ – The Tube & Pipe Journal.

http://www.fma-communications.com/tpj/