On March 19, 2011, The U.S. and allied forces launched 124 Tomahawk cruise missiles at more than 20 targets in Libya, followed by 38 additional missiles in the days to follow. During the opening hours of the Gulf war, the U.S. had launched 288 Tomahawks toward Baghdad. The Navy has more than 3000 Tomahawks in its arsenal and claims that the launched missiles will not be replaced. Admiral Gary Roughead, chief of naval operations told reporters in Washington, “The Tomahawks that were shot are part of our current inventory; there are more than ample replacements for those, more than ample”. The missiles launched were model Raytheon’s BMG-109, which is an older design.

However, according to the navy’s current five year budget plan, it intends to buy 980 of the newest missiles, the Tomahawk Block IV at $1.4 Million each. The weapon is made at Raytheon Missile Systems (CAGE Code: 1F9H2) in Tucson, Arizona. Raytheon has shipped over 2,000 of these missiles to the Navy.

Beyond missile launches, the U.S. used 19 aircraft to strike Libyan air defense targets including three bat-winged B-2 bombers that dropped 45 Boeing made 2,000 pound satellite guided JDAM bombs. According to Air Force Global Strike Command, the bombers flew from Whiteman air force base in Missouri directly to Libya and back without landing. Each B-52 required four refuelings to make the journey.

Also included in the arsenal were four Boeing F-15E and eight F-16CJ Air Force Fighter jets made by Lockheed Martin. The navy also provided Boeing EA-18G Growler electronic jamming jets, while the Marines flew four AV-8B Harrier jets launched from the USS Kearsarge floating in the Mediterranean Sea.

SELF LOCKING HEX NUTS

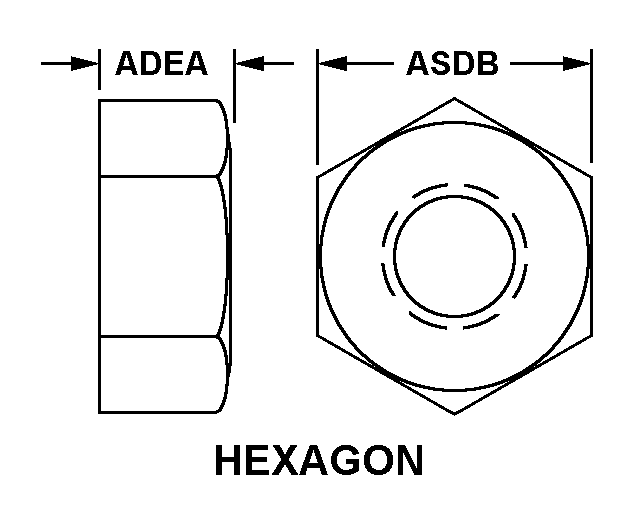

For security purposes, Raytheon will not disclose the exact fasteners used in the Tomahawk missile. Although the details are not classified, we respect their right to secrecy and speak in more general terms. A fastener commonly used in missile production is the self-locking hex nut. Aerospace engineering poses several challenges with components being exposed to extreme shock, vibration, G-force and thermal anxiety, repeatedly without tightening. A design is only as good as its weakest link, which is often a fastener. This is why self-locking hex nuts are used.

The defense department regularly orders fasteners directly through procurement, and any U.S. company with the capability to produce them can potentially become an approved supplier. For most aerospace parts, vendors must be on the Qualified Suppliers List prior to selling to the defense department. The company can submit sample parts to a government inspector to receive this approval. The item below is also a “Critical Application Item” meaning that it is subjected to additional scrutiny, including a source inspection before being used.

There have been a number of recent high-dollar solicitations for self locking hex nuts, but one in particular caught our attention:

| Issue Date | Solicitation # | National Stock # | Quantity | Price | Est. Total |

| 04/12/2011 | SPM5A4-11-T-0019 | 5310-00-245-3505 | 4,590 | $15.60 ea | $ 71,604 |

The exact nomenclature, in government-speak is: NUT, SELF LOCKING, HEXAGON. The nut is is 7/8-9UNC-3B made from nickel alloy with a plastic polyhexamethylene amide locking insert. Unfortunately, by the time you read this, the above contract will be closed, as it expires on 4/26/2010. However, this is the second RFQ for this part in 2011, after DLA not ordering it since September of 2007. It was last supplied by Aircraft Hardware West of Long Beach, CA (CAGE code: 3CUA9), and Triman Industries of New Jersey (0ZBE8) before that.

Two other solicitations of interest are for similar items, the first is a silver treated double hexagon self-locking nut, and the other is a smaller version of the hex nut described above.

| Issue Date | Solicitation # | NSN | Quantity | Price | Est. Total |

| 04/10/2011 | SPM8E6-11-T-4274 | 5310-00-680-4797 | 8,899 | $11.00ea | $ 40,183 |

| 04/15/2011 | SPM5A8-11-Q-1442 | 5310-00-701-5786 | 46,400 | $ 1.07ea | $ 45,639 |

These parts were supplied by Defense Support Services in Arlington, TX (1L3U4), and Kampi Components in Fairless Hills, PA (7Z016) respectively. The key to finding solicitations of this type is to use multiple search terms. We used Federal Supply Class 5310, combined with the keywords, “Nut” and “self locking”. Nomenclature is very important when searching for defense contracts, as the government uses very specific terms to describe items.

Another point of interest is that almost all of the recent contracts for self-locking hex nuts were awarded to distributors, not manufacturers. It appears that a handful of distributors are winning a large percentage of the contracts. Perhaps there is an opportunity for manufacturers to win more of these types of contracts through a direct relationship with the defense department. BidLink will continue to highlight government buying activity for this industry and share it with the readers of Fastener Journal.

BidLink.net is a provider of defense industry information for contractors worldwide. This data includes millions of defense contracts, procurement history, part numbers and vendor details. This unique combination of resources allows BidLink to monitor and extract important information for the defense contracting industry. BidLink.net, based in Washington, D.C., provides bid consolidation, searching and notification services, as well as part number (NSN) lookup to many military activities and thousands of private companies around the world.

This article was written exclusively for Fastener Journal. http://www.fastenerjournal.com